Managing Supplier Risk

3/6/2025

•7 MIN READ

In today’s hyperconnected supply chain world, every delivery isn’t just a product or a service. It’s a promise. A promise that must be kept over time, even under pressure, even when things don’t go as planned. In a globalized context where suppliers can be located across continents, lead times are shrinking, and customer expectations are rising, this promise becomes more fragile and more critical.

Behind every on-time delivery, there are dozens of variables that need to align: production schedules, raw material availability, financial stability, transportation reliability, regulatory compliance, and more. A disruption in any of these can ripple through the entire chain, causing delays, cost overruns, missed targets, or even complete operational standstills. From factory floors in Asia to logistics hubs in Europe, the complexity of supply networks has made companies more exposed than ever.

But here’s the catch: many of these risks are not visible at first glance. A supplier might seem solid on paper but be one delay or one policy change away from becoming a bottleneck. A natural disaster, a cyberattack, or a sudden financial downturn can turn a reliable partner into a point of failure overnight. This is exactly the kind of scenario that characterizes a VUCA (Volatile, Uncertain, Complex, Ambiguous) world. And yet, many companies still rely on outdated processes, manual data tracking, or limited vetting during the supplier selection phase.

Managing supplier risk isn’t just a procurement issue, but it’s a strategic imperative. It determines how resilient a company truly is in the face of uncertainty. And as recent years have shown us, from pandemics to geopolitical tensions, uncertainty is no longer the exception.

That’s why understanding, measuring, and anticipating supplier risk is essential. It's the foundation of a robust, agile, and competitive supply chain.

What Lies Behind a Supplier

Suppliers can bring great value, but they can also introduce significant vulnerability. Managing them effectively means recognizing and addressing the different types of risks they carry.

These risks generally fall into distinct categories:

• Quality: defective or non-compliant products that halt production lines.

• Logistics: shipping delays, port congestion, raw material shortages.

• Financial reliability: a financially unstable supplier might suddenly fail to meet agreements.

• Dependency: relying on a single supplier for a key component exposes the company to severe risks.

• Geopolitical and environmental risks: wars, earthquakes, pandemics, energy crises, regulatory instability.

These risks are not static. They evolve constantly, shaped by a mix of global trends, supplier behavior, market volatility, and internal strategic decisions. A supplier that was low-risk last quarter could become a major liability today due to shifting regulations, financial instability, or changes in their own supplier base. Likewise, a geopolitical event on the other side of the world could suddenly impact a seemingly stable partner due to cross-border dependencies.

In this ever-shifting context, risk management cannot be a one-time assessment or a checklist completed during onboarding. It needs to be a continuous process, data-driven, and deeply integrated into procurement and supply chain decision-making. Companies must be able to detect early warning signals, reevaluate suppliers regularly, and respond quickly when conditions change.

Risk Management: From Reactive to Proactive

Both literature and business best practices agree: companies must shift from reactive to proactive risk management. That means mapping risks across the supply chain, scoring suppliers based on risk categories and monitoring how these scores evolve over time.

This approach allows companies to:

• anticipate disruptions

• define mitigation strategies (audits, co-design, business continuity plans)

• select more resilient and reliable suppliers

• reduce the overall cost of risk

The Problem? Data

To accurately assess risk, you need information. A lot of it. Not just quantitative KPIs, but weak signals too: recurring delays, management changes, colleague feedback, incomplete audits, unusual behavior. These data points are often scattered across emails, spreadsheets, or individual memories.

That’s where Soource comes in.

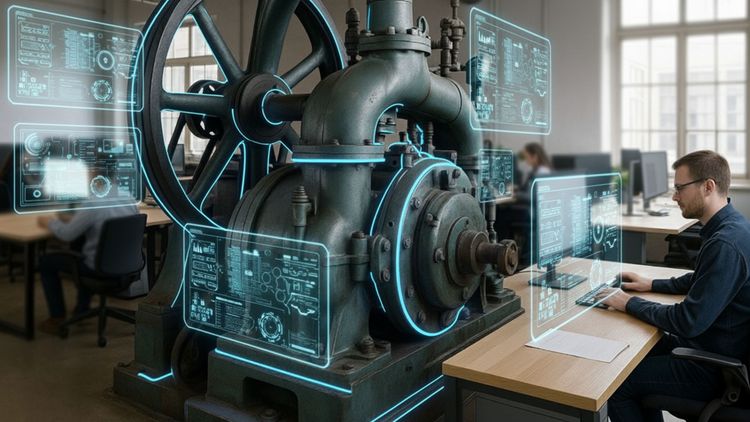

Soource transforms supplier risk management by making information gathering effortless and automatic. Instead of manually compiling fragmented data from emails, spreadsheets, or outdated systems, Soource reads and interprets supplier responses directly from your inbox.

With just a few clicks, purchasing teams can send out mass Requests for Information or Quotations. Soource’s AI then analyzes the replies, extracts key insights, and updates supplier profiles in real time. No more digging through emails or chasing documents. The system learns continuously, enriching your supplier database with each interaction.

Soource doesn’t just help you find suppliers, it builds a living, learning map of your supply base. One that keeps you informed, up to date, and ready to act. Because resilience isn’t just about having backup plans. It’s about having the right information, at the right time.

FAQ

We have collected the most frequently asked questions here, but don't hesitate to contact us if you have any doubts or want to know more about Soource.

Is Soource compatible with my ERP (Enterprise Resource Planning or Procurement Suite)?

Yes, Soource is compatible with major ERP and procurement software like SAP Ariba, Jaggaer and other enterprise systems. You can integrate it for bidirectional data exchange or use it as a plug & play solution, without the need for integration.

Are my data on Soource protected and secure?

Absolutely. All corporate, personal and supplier data remains your property and is processed according to GDPR and European regulations. Generic data is anonymized to improve platform and Soource community performance.

Where does supplier data on Soource come from?

Soource's database combines:

- Certified and public sources

- Data collected from intelligent web crawling

- Information automatically extracted from corporate emails

Today Soource offers the largest database of Italian companies with direct email contact.

Can I attach files to RFI, RFQ or RFP on Soource?

Yes, you can attach documents in any format to your requests (RFI - Request for Information, RFQ - Request for Quotation or RFP - Request for Proposal). In particular, for RFIs, it is recommended to include a technical specification sheet of the product to get more detailed responses from suppliers.

Can I send follow-ups to suppliers with Soource?

Yes. With Soource you can filter suppliers who haven't responded and send a mass follow-up in one click. This helps you double the response rate, up to 80% on average, improving RFI, RFP and RFQ management.

Is Soource compliant with the European AI Act?

Yes. Soource's artificial intelligence is compliant with the European Union's new AI Act, falling into the zero-risk category, as it only supports internal activities and does not automate outward processes or critical decisions.

Why use Soource for RFI and RFP?

With Soource you can:

- Create RFI (Request for Information) and RFP (Request for Proposal) in just a few clicks

- Send them automatically to selected suppliers

- Analyze responses with artificial intelligence

- Extract and compare certifications, availability, technical capabilities

You save time and identify the best suppliers more quickly.

Can I also use Soource for RFQ?

Yes. Soource also supports RFQ (Request for Quotation) to request economic offers. The platform automates:

- RFQ sending

- Response reception and reading

- Comparison of prices and conditions